Overview

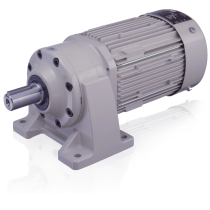

Since the official launch of the Altax® reducer in 1993, a new product of this series of reducers has been launched. The new series integrates the compact structure of the Altax α series and adopts "double support" to directly support the heart of the reducer, the "curve plate", from both sides. The motor with brake is equipped with a low-noise brake as standard. Gear motors that are both small and low-noise are favored in a wide range of fields.

Product Features:

Structure:

The use of arc-shaped internal gears eliminates inter-tooth wear and achieves smooth transmission contact. The reduction parts are made of high-carbon and high-chromium bearing steel that is wear-resistant and has good performance. The meshing rate is 2~3 times that of the involute gear, and the impact load is dispersed by most gears, which is reliable and durable. The meshing rate of the involute gear is low. Once an impact load occurs, the impact force is concentrated on 1~2 teeth.

Low noise:

The use of double support and planetary gear drive makes the gears mesh smoothly and greatly increases the number of tooth meshing during transmission. The low-noise brake is selected as standard configuration to achieve low-noise operation.

Small size in the industry:

Small size, compatible with the main dimensions of the popular Altax α series, good interchangeability. The concentric shaft structure, which is different from the general gear motor, realizes the smallest flange size in the industry. The flange center coincides with the motor center, and the volume is getting smaller and smaller.

Multiple reduction ratios:

You can choose from a low reduction ratio of 1/3 to a high reduction ratio.

Free installation direction:

Because all models have no restrictions on installation direction, they can be freely designed and installed to suit different purposes of customers.