Overview

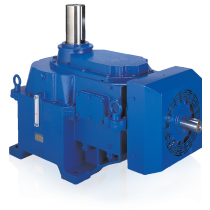

The reducer for SFC air cooler is a special reducer in the PARAMAX9000 series family of Sumitomo reducers. It is designed and developed based on the PARAMAX9000 series prototype according to the actual working conditions of the air cooler and the special requirements for the reducer. It is a reducer for air cooler fan drive.

Beier series product features:

Designed according to the requirements of air cooler fan drive, simple selection:

The SFC air cooler special series reducer is a special reducer designed for air cooler fan drive. According to the motor power and fan diameter, it is convenient to select the reducer that suits the customers needs from the SFC special sample (G2202C).

Anti-vibration design:

Increased output shaft bearing span. Even if the fan is designed with excellent balance, vibration will still occur during operation. Through the increased output shaft bearing span design, the SFC series reducer can better withstand the vibration generated by the fan operation.

Flat mounting surface design:

Considering the ease of installation and compact structure, the SFC series reducer adopts a different design structure. Even if optional parts such as backstops and shaft end pumps are selected, the flat mounting surface structure can still be guaranteed.

Good heat dissipation design:

Considering the particularity of the reducers installation position inside the cooling tower, the wind generated by the cooling tower fan is difficult to reach the reducer installation position.

The SFC series reducer has an increased housing area, lowered oil level to reduce heat loss caused by liquid agitation, and a large oil capacity, which reduces the heat generation of the reducer to a very low level. And it has good heat dissipation performance.

Low noise

Compared with previous products in the same series, the noise is reduced by 3-5 dB.

Through the paired gear processing technology, the teeth between the gears are tightly meshed, which effectively reduces the noise when the gears are meshed.

Through finite element (FEM) analysis, the deformation of the housing under load is reduced to a very small amount. The gear teeth are fully and completely meshed, and the natural vibration frequency of the machine is reduced.

Convenient maintenance:

It can run continuously for 9,000 hours without maintenance. (The general maintenance cycle of ordinary gearboxes is 5,000 hours)

The oil filling hole, oil drain hole and oil mark are located on the outer extension of the housing on the output shaft side, ensuring that the maintenance operation is not affected by the maintenance work position.

Since the observation window is located above the oil level, it is not necessary to drain the oil, and the operation inside the gearbox can be checked through the observation window.

The direction of the motor can be checked without disassembling the motor. (This function requires a special type of coupling. If you have this requirement, please inform our sales staff when ordering)

Can be used with variable frequency motors

The lubrication design of the SFC series is suitable for variable frequency motors under different speed environments.